RSI is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

It’s the Stanley Cup finals, some National Hockey League players have complained about the conditions of the ice rinks. Problems may arise from humidity, leakage, or wrong ice temperatures. 1 The refrigeration technology underlying ice rinks is in fact the same as in refrigerators and air conditioners.

How Do Ice Rink Refrigeration Systems Work?

The main difference between ice rinks and refrigerators or air conditioners is that the refrigerant doesn’t cool the ice directly. Instead, the refrigerant cools brinewater, which is an anti-freeze agent that is pumped through pipes underneath the ice. These pipes are typically embedded in a concrete or sand base. The system consists of three main parts:

- Chillers

- Steel pipes

- Brinewater

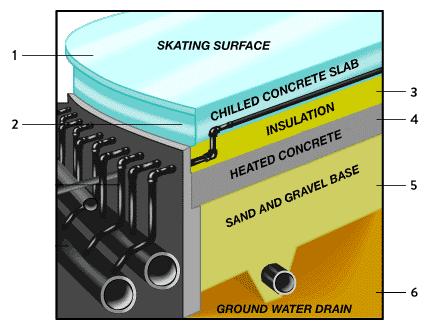

The floor of an ice rink includes the following elements (top to bottom):

- Skating surface

- Chilled concrete slab

- Insulation

- Heated concrete

- Sand and gravel base

- Ground water drain

To freeze the rink surface, the refrigeration system pumps 9,000 gallons of freezing brinewater through the pipes and on top of the ice-bearing concrete slab. Since the slab sits between the skating surface and the insulation, ice can expand and shrink depending on temperature or time requirements. The brinewater keeps the slab’s temperature just below 32F.

Get Started on the Path to a New Career

Fill out our form to learn how we can help you change your life.

Underneath the insulation, a heated concrete layer keeps the area below the ice from freezing, which could damage the rink structure. Below that, there is a base layer of gravel and sand, which has a drain at the bottom. When the skating surface is defrosted, the brinewater is heated, which warms up the under layer of the ice. 2

Hockey Ice Rink Design & Maintenance

Ice rinks used by the NHL must follow strict requirements regarding shape, size, surrounds, maintenance, and temperature. Converting a sports arena into a professional ice rink is quite complex.

To make an ice rink, water is carefully released onto the floor to ensure ideal thickness. If it’s too thick, it needs more energy to remain frozen and may get soft on top; too thin and skaters could cut straight through the ice. The process involves several steps, including spray-painting marking and logos. A rink surface will need between 12,000 and 15,000 gallons of water.

Temperature and humidity conditions are crucial for creating and maintaining an ice rink. The skating surface is ideally between 24 and 26 F while the indoor temperature is about 63 F and indoor humidity about 30%. Even small changes can make a huge difference. High humidity can create fog over the ice. Hot weather outside may soften the ice inside as arena doors open. 3

Ice gets damaged during a game. To maintain an ice rink, it is first manually resurfaced with scrapers, towels, squeegees, and a water hose. Then, ice-resurfacing machines shave, scrape, wash, and squeegee the rink before it gets a fresh layer of water. The NHL requires that the ice is resurfaced with two machines before the game, after warm-ups, between periods, and after a game. 4

Ice Hockey – A Workplace for You?

If you are a hockey fan or want to work in an unusual environment, you might want to consider using your refrigeration training to work at an ice hockey rink. The refrigeration technology of an ice rink is quite similar to that of other refrigerators or air conditioners, yet your workday may look pretty different.

Additional Sources

1 – http://www.sporttechie.com/2017/02/28/sports/nhl/its-been-a-rough-season-for-nhl-ice/

2 – http://entertainment.howstuffworks.com/ice-rink2.htm

3 – http://entertainment.howstuffworks.com/ice-rink4.htm

4 – http://entertainment.howstuffworks.com/ice-rink6.htm

Image Credit: http://entertainment.howstuffworks.com/ice-rink2.htm

This blog has been labeled as archived as it may no longer contain the most up-to-date data. For a list of all current blog posts, please visit our blog homepage at https://www.rsi.edu/blog/